Windings are necessary to make all these machines to run and generate the output. There are multiple classifications of these winding machines like automatic, semi-automatic, manual, computerized and non-computerized. MachinesĮlectric motor winding machines are in more prominence these days and they became a part of our day-to-day life. These wires perfectly satisfy the properties of resistivity, inductance, temperature conditions and many other factors.

MOTOR WINDING THEORY IN HINDI GENERATOR

In many of the electrical machines such as inductors, generator and transformers copper enameled windings are used. And for round copper wires, they gain their shape after several stages of cold drawing. Rectangular shaped wires are made of extrusion procedure where a wire rod is hard-pressed via a die to gain its final shape. Mostly motor winding wire is made of copper. Now, we shall know more about how the motor winding wire is made and what are they made of? Basically, the raw material which is used for both the circular and rectangular wire is either aluminum or copper. And when there exists an open circuit, the range will be of more than 2K ohms or infinite. When the readings are zero, there happens a short circuit. Place the meter on ohms and usually, the range will be in the order of 2 -3 ohms.

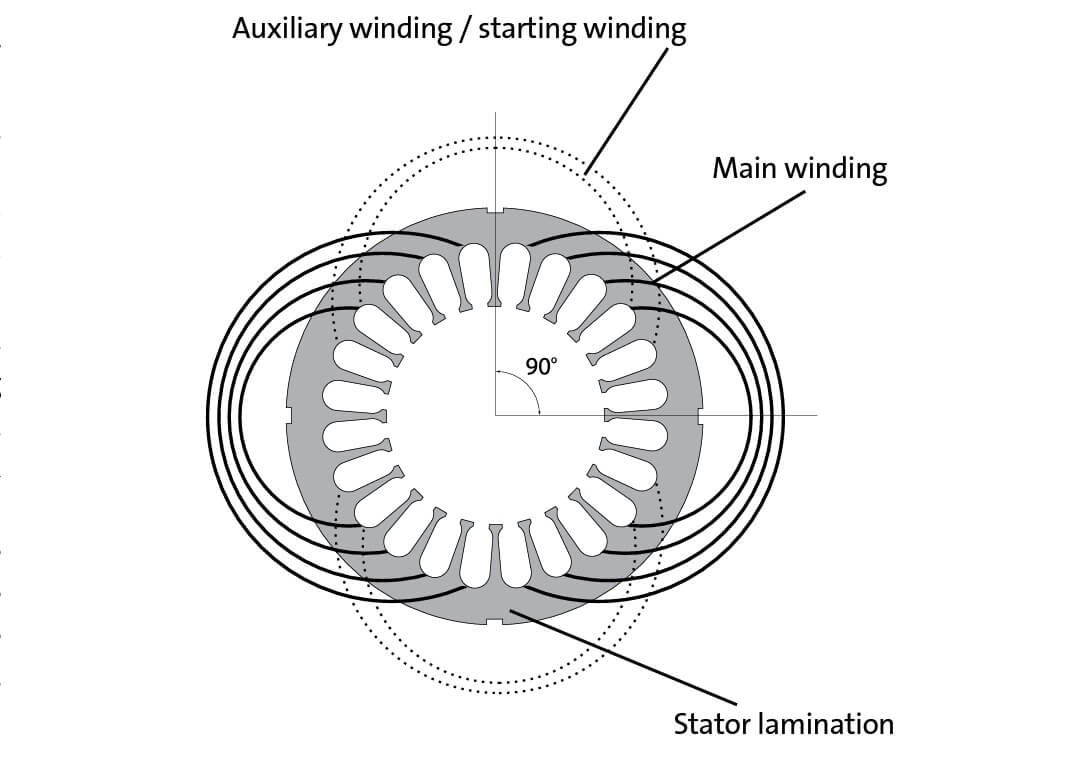

Thus, this article is all about the concept of motor winding theory, its design, calculation and the clear approach of knowing it. Motor windings hold utmost prominence in the operation of the motor and there also exist various types of windings used in motors. So, a machine will generate the output when there is a connection between the electric current and the magnetic field and this connection happened through coil windings.

And an electrical machine is the one which is crucial to transform one form of energy into another form. Advancement of technology has shown invention for multiple kinds of machines. These days human life is completely revolving around machines and technology.

0 kommentar(er)

0 kommentar(er)